Borax, also known as sodium tetraborate, is a naturally occurring mineral that has been used for centuries in various industries, including woodworking. Recently, woodworkers have discovered that using borax as a pretreatment for laser engraving can greatly enhance the final product. By darkening the engraved areas, the contrast between the engraved and non-engraved parts of the wood is increased, resulting in a more striking and professional-looking final product.

The process of using borax for laser engraving is relatively simple. First, the wood must be cleaned and sanded to ensure that the surface is smooth and free of debris. Next, a solution of borax and water is applied to the surface of the wood. The solution is then allowed to sit on the wood for several minutes, depending on the desired level of darkening. After the solution has been allowed to sit, it is then wiped off with a clean cloth.

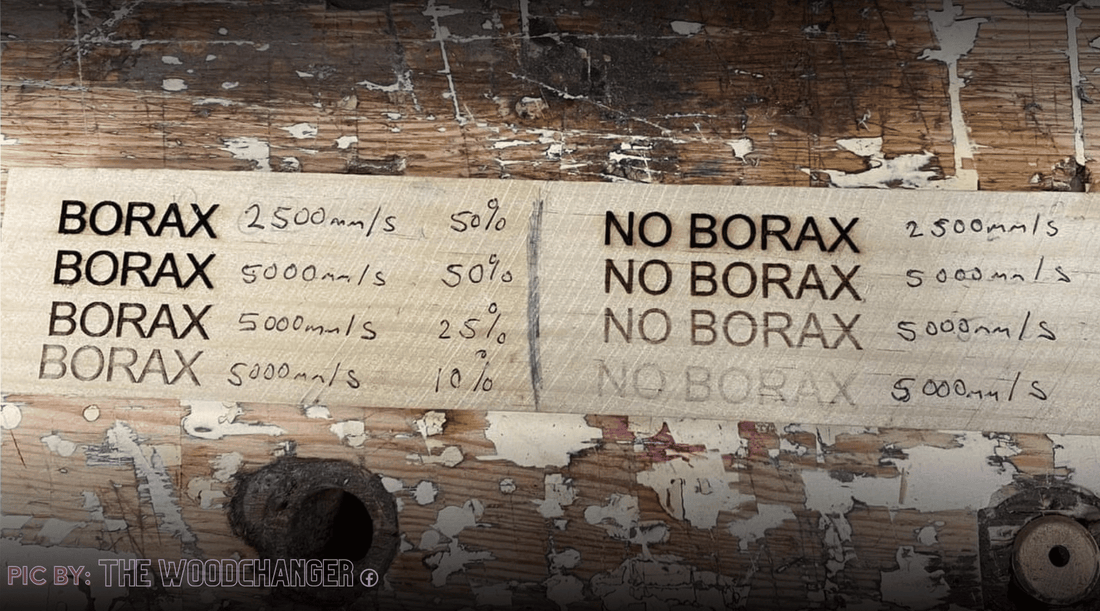

The concentration of borax in the solution can be adjusted to achieve different levels of darkening. For a light darkening, a solution of 2-3% borax in water can be used. For a more dramatic darkening, a solution of 5-10% borax in water can be used. It is important to note that the higher the concentration of borax in the solution, the longer it should be left on the wood before being wiped off.

Once the borax solution has been applied and wiped off, the wood is ready for laser engraving. The laser engraver is set to a lower power setting than normal, as the borax has already darkened the wood. This allows for a more precise and detailed engraving, as well as a longer lifespan for the laser engraver.

It is important to note that while borax is a natural mineral, it can be toxic if ingested or inhaled in large quantities. Therefore, it is crucial to handle borax with care and use it in a well-ventilated area or take proper ventilation measures. It is also important to wear gloves and a mask to protect yourself from inhaling the borax dust. Additionally, you should avoid using borax on wood products that will come into contact with food or other items that may be ingested. It is always best to use caution when working with any chemical and to follow the manufacturer's recommendations and safety precautions.

It is important to note that the borax solution should be applied in a thin, even layer, and that the wood should be completely dry before engraving. After you are done engraving make sure to seal the wood with a clear coat.

Note: In the UK, borax is classified as a substance of very high concern and is not available for sale to general consumers. As a result, some laser engravers have turned to using baking soda as an alternative. While this method has shown some promise, it is important to note that the best solution for achieving deep and dark engravings on wood may vary depending on the specific laser engraver and the type of wood being used. If you decide to use baking soda, a good starting point is to mix 10% baking soda with water and test the solution on a small area of the wood before proceeding with the full engraving. If you have really refined your baking soda method, we would love to hear what you have come up with. Leave us a comment or email us.

Overall, using borax as a laser engraving technique on wood can be a great way to achieve deeper, more defined engravings. It is a simple and cost-effective solution that can be easily incorporated into any laser engraving process. So, if you're looking to add more depth and dimension to your wood engravings, give borax a try and see the difference it makes.

1 comment

Presumably this is for laser engravers based on CO2 lasers rather than laser engravers based on diode or LED lasers (much different wavelength and absorption characteristics).